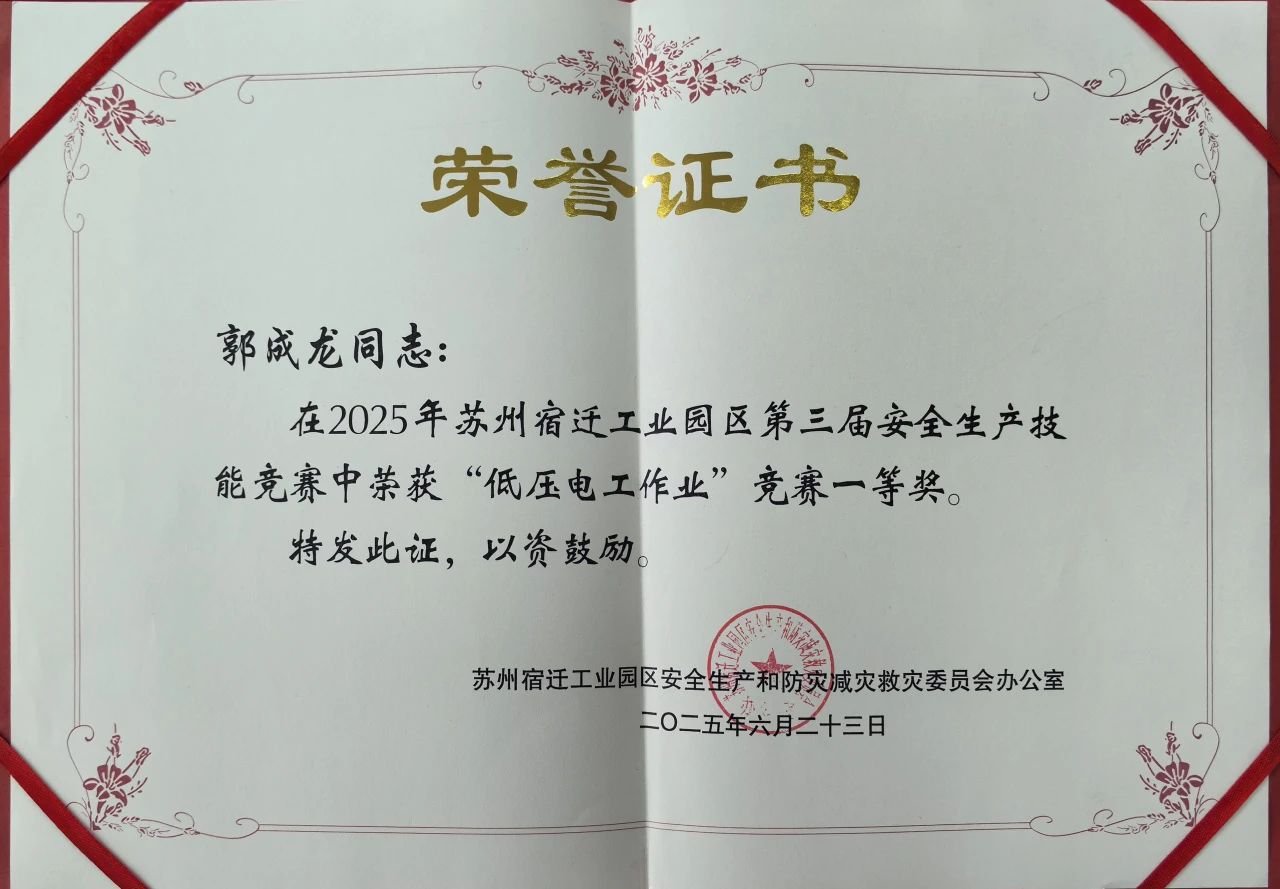

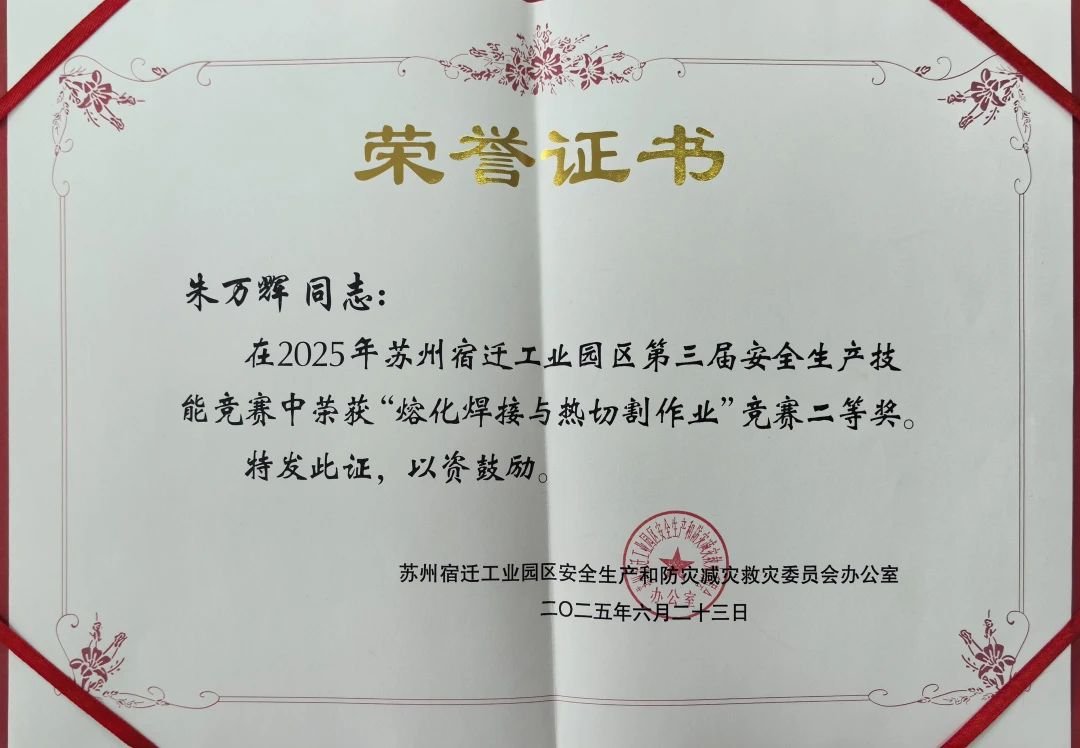

On June 16th, the third safety production skills competition of Su-Shu Industrial Park came to a close at the Safety Production Qualification Examination Center in Suqian City. After multiple rounds of intense competitions, Guo Changlong from the Equipment Department of China Shipping Marine Equipment (Jiangsu) Co., Ltd. won the first prize in the "Low Voltage Electrical Work" competition with outstanding performance, while Zhu Wanhui from the Production Department won the second prize in the "Fusion Welding and Thermal Cutting Work" competition with his superb skills. This excellent result not only confirmed CSAC's strategic positioning of "Technology as the Foundation, Talent Enhancing Safety", but also demonstrated the profound foundation of the enterprise's safety production management system.

This competition is organized by the Su-Su Industrial Park Management Committee. It focuses on the core capabilities of safety production and sets up four practical modules:

Welding and Thermal Cutting Operations: Based on the high-temperature melting scenario, it rigorously tests the special operation norms and dynamic risk control capabilities;

Low-Voltage Electrical Work: Simulating the sudden occurrence of electrical faults, it focuses on examining the emergency response logic and the accuracy of safe operations;

Hazard Investigation Tournament: Through the replication of real production lines, it competes in the "sharp eyes" style of hazard identification and closed-loop governance efficiency;

Technical elites from over 20 enterprises in the park compete on the same stage, triggering a "promoting learning through competition, training troops through battle" craze for improving safety skills.

"Safe production is an inherent belief deeply rooted in our company's culture." Vice President Yang of CSAC Group emphasized at the award ceremony, "CSAC has always regarded safety as the lifeline for achieving high-quality development. Through the establishment of a 'three-in-one' safety management system (building a foundation with regular training, controlling risks through standardized procedures, and empowering with intelligent platforms), we have transformed the safety concept into the conscious behavior of all employees." The deputy director of the equipment department, Guo Chenglong, who received the award, shared his thoughts: "Every point on the competition field comes from thousands of times of standardized operations in daily life. We need to turn the competition standards into work habits."

At the summary and commendation meeting, Mr. Yang clearly stated: "We should transform the competition experience into 'reproducible and scalable' safety production standard templates." The company then initiated three major actions: Skill standardization: Compile the "Special Operations Safety Operation Diagram Manual", converting the competition scoring points into job SOPs; Management intelligence: Pilot the AI safety monitoring system in the welding workshop to promptly correct improper operations; Cultural infiltration: Conduct the "Safety Red Card Battle" competition, providing special rewards for various process improvement proposals put forward by employees. Safety is not a multiple-choice question, but a mandatory one. General Manager Lu of China Shipping Anchor Chain emphasized at the mobilization meeting, "Safety production is the top priority for the development of the enterprise." We will take this competition as a new starting point and continue to deeply explore potential safety hazards within the enterprise to safeguard the safety lifeline of the enterprise. At the end of the meeting, the company commended the outstanding individuals who performed well in the competition, awarded them honorary certificates and bonuses, and called on all employees to follow the example of the advanced individuals and continuously implement the excellent experiences and practices from the competition into daily safety production work.

To promote the transformation of safety culture from "regulatory constraints" to "value recognition", the company innovatively launched the "Safety Ecosystem" construction: Leadership by example: Led by the vice president of CSAC Group, the heads of various departments formed a "Safety Supervision Team" to conduct the "Cross-Questioning of Safety Knowledge" activities in the workshops. Cross-enabling: Establish a "Department Safety Alliance", consisting of departments such as production, equipment, and quality inspection, and conduct random checks on safety knowledge through the "Question and Answer" format. This competition result fully demonstrates the effectiveness of our company's safety training system and standardization construction. We should take this award as an opportunity to further strengthen the concept that "safety is efficiency", convert the competition experience into standard norms for daily work, and promote the safety awareness and operational skills of all employees to reach a new level. In the future, CSAC will take this event as a new starting point, continue to implement the concept of "Everyone Talks about Safety, Everyone Knows How to Respond to Emergencies", with technology as the shield and responsibility as the spear, continuously consolidate the safety production defense line, and promote safety production to leap from "passive defense" to "active intelligent control"!